Cutting Device (EOD/IEDD)

Applied New Technologies AG (ANT AG)

MACE – Mobile Abrasive Cutting Equipment

ANT AG produces system for WAS (Water Abrasive Suspension) cutting process. It develops cutting devices, robotics and all kinds of gripper equipment or carrier systems in the field of special-purpose machinery.

ANT AG produces system for WAS (Water Abrasive Suspension) cutting process. It develops cutting devices, robotics and all kinds of gripper equipment or carrier systems in the field of special-purpose machinery.

The MACE system is particularly suited for cutting large-calibre unexploded ammunition. The system allows to remove or deactivate the fuse remotely, risk-free and safe. The cutting devices in the MACE system are specially designed for the EOD (Explosive Ordnance Disposal) sector.

Mini MACE System

The mini MACE combines an abrasive mixing unit and a high-pressure pump in a single casing. The working pressure of the unit, which is driven by an internal combustion engine, is 450 bar.

The mini MACE combines an abrasive mixing unit and a high-pressure pump in a single casing. The working pressure of the unit, which is driven by an internal combustion engine, is 450 bar.

The mini MACE is suited for, for example, the cutting and opening of pipe bombs, hand grenades or potentially hazardous objects such as unconventional explosive devices in the form of fire extinguishers and cases. In principle, all the cutting devices offered by ANT can be combined with the mini MACE system. The mini MACE are specially designed for the IEDD sector.

Midi MACE System

The midi MACE combines an abrasive mixing unit and a high-pressure pump in a single casing. The working pressure of the unit, which is driven by a battery-powered electric motor, is 120 bar.

The midi MACE combines an abrasive mixing unit and a high-pressure pump in a single casing. The working pressure of the unit, which is driven by a battery-powered electric motor, is 120 bar.

The midi MACE is suited for, for example, the cutting and opening of thin-walled containers and potentially hazardous objects, such as unconventional explosive devices in the form of fire extinguishers and cases.

The cutting device is specially designed for the IEDD sector.

Micro MACE System

The micro MACE combines an abrasive mixing unit, a high pressure pump and a nozzle holder in a single casing. The working pressure of the unit, which is driven by a battery-powered electric motor, is 80 bar.

The micro MACE combines an abrasive mixing unit, a high pressure pump and a nozzle holder in a single casing. The working pressure of the unit, which is driven by a battery-powered electric motor, is 80 bar.

The micro MACE is suited for, for example, the puncturing of thin-walled containers and potentially hazardous objects, such as unconventional explosive devices.

The cutting devices are specially designed for the IED application range.

Cutting Devices

MANIPULATORS – Linear Manipulation System

The linear manipulation system is perfectly suited for detaching complex structures, such as windows, manholes, cut-thoughs and circular sections.

The linear manipulation system is perfectly suited for detaching complex structures, such as windows, manholes, cut-thoughs and circular sections.

With its high flexibility, it can easily adapt to conditions on-site. The simple assembly operation is performed by means of tensioning belts. The system’s adaptation to the internal diameter is possible.

MANIPULATORS – Chain Manipulation System

The chain manipulation system is the system of choice for rotationally symmetrical geometries, especially pipes. The chain enables flexible application on external diameters between 400 and 1500 mm

The chain manipulation system is the system of choice for rotationally symmetrical geometries, especially pipes. The chain enables flexible application on external diameters between 400 and 1500 mm

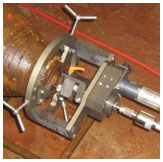

MANIPULATORS – Circular Cutter

The chain manipulation system is the system of choice for rotationally symmetrical geometries, especially pipes. The chain enables flexible application on external diameters between 400 and 1500 mm

The chain manipulation system is the system of choice for rotationally symmetrical geometries, especially pipes. The chain enables flexible application on external diameters between 400 and 1500 mm

MANIPULATORS -Multiflex Circular Cutter and Multiflex Circular Cutter PLUS

The MULTIFLEX circular cutter and the MULTIFLEX circular cutter PLUS are further developments of our circle cutter, offering numerous possible applications. Thanks to the click system no tools are required for assembly and disassembly.

The MULTIFLEX circular cutter and the MULTIFLEX circular cutter PLUS are further developments of our circle cutter, offering numerous possible applications. Thanks to the click system no tools are required for assembly and disassembly.

The MULTIFLEX circular cutters are available only in combination with the MACE 3-component system or as accessory for those already using a MACE system.

MANIPULATORS – Vacuum Circular Cutter

The vacuum circular cutter was especially developed for the usage in combination with our midi MACE equipment.

The vacuum circular cutter was especially developed for the usage in combination with our midi MACE equipment.

This cutting device easily and quickly performs circular cuts in the object being worked on. Its light weight and small dimensions enable the user to fix it on clean, even and plain surfaces (e. g. cars) by a vacuum sucker (manually locked).

MANIPULATORS – Base Fuse Manipulator

The base fuse manipulator was developed for cutting SAP, MC, GP and AP bombs. After it is applied to the base of the bomb, the water abrasive jet cuts out the detonator. Alternatively, the manipulator can be configured to cut away the entire bomb base together with the detonator.

The base fuse manipulator was developed for cutting SAP, MC, GP and AP bombs. After it is applied to the base of the bomb, the water abrasive jet cuts out the detonator. Alternatively, the manipulator can be configured to cut away the entire bomb base together with the detonator.

CUTTING TABLES – 3-Axis Cutting Table

This cutting table is the perfect solution for 3 dimensional contours. With this system, the required geometries can be remotely cut, divided and processed. Its modular design facilitates rapid assembly and dismantling as well as setting up for the cut.

This cutting table is the perfect solution for 3 dimensional contours. With this system, the required geometries can be remotely cut, divided and processed. Its modular design facilitates rapid assembly and dismantling as well as setting up for the cut.

CUTTING TABLES – 2-Axis Cutting Table

This cutting table has been designed for two-dimensional contours. One of its major plus points is its extremely low weight with the associated ease of handling and mobility. The table can be assembled and dismantled without any tools. The new construction enables the frame to be positioned in advance by means of a simple click system.

This cutting table has been designed for two-dimensional contours. One of its major plus points is its extremely low weight with the associated ease of handling and mobility. The table can be assembled and dismantled without any tools. The new construction enables the frame to be positioned in advance by means of a simple click system.

ROV’S – tEODor ROV connection

Our mini MACE can also be remotely driven by the telerob ROV up to the object to be cut. tEODor (telerob explosive ordnance disposal and observation robot) was developed 6 years ago and is especially suited for deactivating explosive devices of all kinds.

Our mini MACE can also be remotely driven by the telerob ROV up to the object to be cut. tEODor (telerob explosive ordnance disposal and observation robot) was developed 6 years ago and is especially suited for deactivating explosive devices of all kinds.

The mini MACE can either be strapped onto the back of the tEODor or fastened onto a special-purpose trailer.

ROV’S – Cutting with ANDROS (ROV)

In the USA there are more than four hundred bomb disposal squads. About fifty percent of them have robots. They mainly work with theANDROS 6 A from the firm Remotec.

In the USA there are more than four hundred bomb disposal squads. About fifty percent of them have robots. They mainly work with theANDROS 6 A from the firm Remotec.

Our mini MACE can be coupled withANDROS via a trailer and hence offers the safe option of also being able to open up Large Vehicle Bombs (LVB).

ROV’S – ROV project: microMACE & PackBot

micro MACE & PackBot EOD: this combination is currently being evaluated jointly with the company ELP (European Logistic Partners) in Wuppertal, Germany. ELP is a certified distribution and service partner of the PackBot manufacturing company iRobot in theUSA.

micro MACE & PackBot EOD: this combination is currently being evaluated jointly with the company ELP (European Logistic Partners) in Wuppertal, Germany. ELP is a certified distribution and service partner of the PackBot manufacturing company iRobot in theUSA.

The objective of the project is the combination of the ROV with a specially adapted micro MACE system for puncturing potentially hazardous objects such as USBV’s in the form of e.g. gas cartridges.

Special Purpose Product

Our Special-Purpose Machinery division designs and manufactures the optimum manipulator as a nozzle guide for nearly every cutting task. With this we offer our customers the flexibility and individuality necessary toadvance their projects.

Our Special-Purpose Machinery division designs and manufactures the optimum manipulator as a nozzle guide for nearly every cutting task. With this we offer our customers the flexibility and individuality necessary toadvance their projects.

ANT can offer you a tailored concept for easy, safe cutting to meet project conditions and requirements.